| Model | Flow rate | Head | Speed | Efficiency | Power |

| MJ-1 | 20m³/h | 18m | 1430rpm | 42% | 3kw |

| MJ-2 | 30m³/h | 11m | 1430rpm | 38.2% | 3kw |

| MJ-3 | 40m³/h | 22m | 1440rpm | 41% | 7.5kw |

| MJ-4 | 50m³/h | 12m | 1440rpm | 55.9% | 5.5kw |

| MJ-5 | 80m³/h | 21m | 1460rpm | 55% | 11kw |

| MJ-6 | 90m³/h | 15.6m | 1460rpm | 51% | 11kw |

| MJ-7 | 110m³/h | 24m | 1470rpm | 54% | 18.5kw |

| MJ-8 | 120m³/h | 28m | 1470rpm | 56% | 22kw |

| MJ-9 | 160m³/h | 39m | 1480rpm | 52% | 45kw |

| MJ-10 | 200m³/h | 25m | 1480rpm | 49% | 37kw |

| MJ-11 | 240m³/h | 31m | 1480rpm | 50% | 45kw |

| MJ-12 | 320m³/h | 17m | 1480rpm | 57% | 37kw |

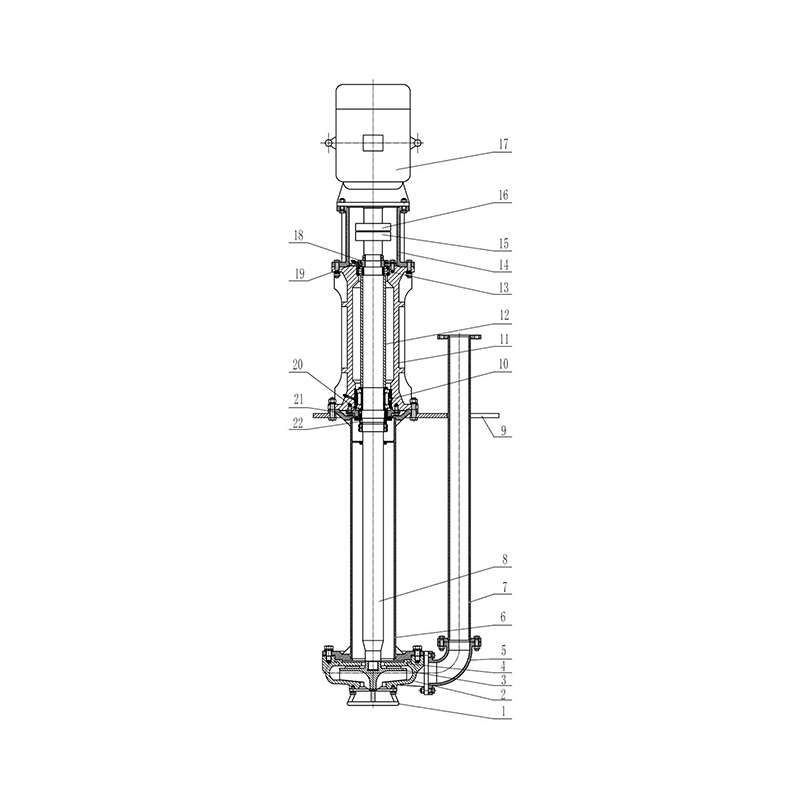

Structure

|

1. Bracket 2. Pump body 3. impeller 4. Rear cover 5. Elbow 6. Connecting pipe 7. Outlet pipe 8. Shaft 9. Fixing plate 10. Double-row tapered roller bearing 11. Bearing body 12. Distance sleeve 13. Single-row cylindrical roller bearing 14. Motor frame 15. Pump coupling device 16. Electric coupling device 17. Motor 18. Bearing bush 19. Bearing cover 20. Oil seal 21. Seal gland 22. Mudguard |

The Role of a Slurry Pump in an Aac Block Production Line:

- Role of Slurry Pump:

Transports the liquid mixture (slurry) of cement, lime, sand, water, and other additives from the mixing station to the casting molds or other processing areas.

- Process It Belongs To:

Mixing and Casting process, specifically for transferring the prepared slurry into the molds for forming aerated concrete blocks.

- Related Equipment Before:

Mixing Equipment – for blending raw materials (cement, lime, sand, and water) to form a homogeneous slurry.

Screw Conveyors – for transporting dry raw materials into the mixing equipment.

- Related Equipment After:

Casting Molds – used for pouring slurry, allowing it to set and form aerated concrete blocks.

Autoclave – where the molded blocks are cured under high-pressure steam after setting.