| Maximum specification (L x H x W)/mm | 6000 x 1500 x 600 |

| Minimum thickness/mm | 100 |

| Maximum vertical travel/mm | 1700 |

| Maximum clamp travel/mm | 80 |

| Effective clamp travel/mm | 50 |

| Maximum separating stroke/mm | 10 |

| Driving method | Fully hydraulic |

| Conveying method of green cake | Transfer cart |

| Total power/kW | 26 |

| Maximum dimension(L x H x W)/mm | 7907 x 3015 x 3153 |

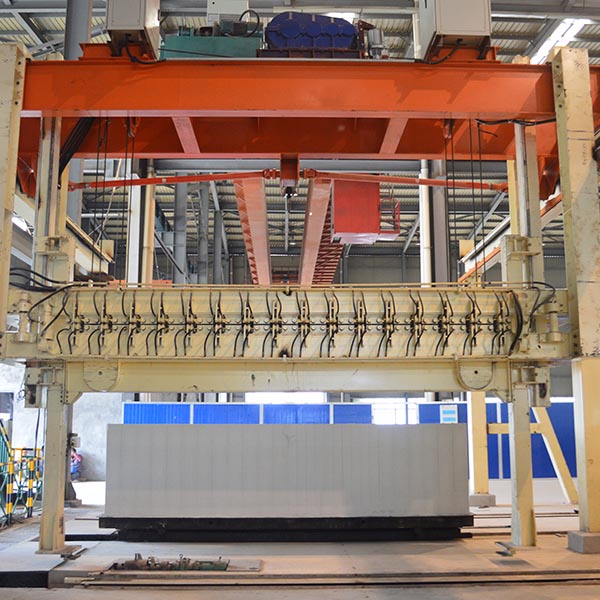

The Role of the Separator in the AAC Block Production Process:

Separates the cut aerated concrete blocks or panels from the cutting waste. It ensures clean separation of blocks/panels, allowing for waste material to be removed for recycling or disposal.

Process It Belongs To:

Block/Panel Cutting and Handling process, specifically after the cutting stage to remove and manage waste.

Related Equipment Before:

Cutting Machine – for cutting the aerated concrete mass into blocks or panels of the required dimensions.

Tilt Table – for turning the aerated concrete onto its side for efficient cutting.

Related Equipment After:

Autoclave – used to cure separated blocks/panels under high pressure and elevated temperature.

Waste Recycling System – for processing the waste material from the separator for reuse in the production process.

Features

- The separator can clamp the blocks reliably and evenly, with a small average error, ensuring the separation quality.

- Each pair of clamps is set with a separate control on the hydraulic system, and the position of clamping on a certain blank is arbitrary.

- The clamping force of the separator can be adjusted freely, and the pressurization will be automatically stopped after reaching the set clamping force.

- Depending on the operating conditions, the separation speed, stroke, and braking force may all be changed.

- The blocks are lifted and lowered by a hydraulic drive, with an imported encoder for precise control and adjustable lifting power and speed.

- The separator offers automatic/manual modes, with filters that alert and trigger action when clogged.