The Role of the Friction Wheel in The AAC Block Production Process:

The Friction Wheel is used to move or rotate large equipment such as autoclaves or molds. It provides the necessary torque through friction to control the movement of heavy machinery in a stable and controlled manner.

- Process It Belongs To:

Autoclaving and Curing Process, where the aerated concrete blocks are subjected to high-pressure steam curing to strengthen them. - Related Equipment Before:

Cutting Machine – for cutting the aerated concrete into blocks or panels before they enter the autoclave.

Autoclave Transfer Trolleys – for transporting the cut blocks to the autoclave. - Related Equipment After:

Autoclave – for steam curing the aerated concrete blocks.

Unloading Trolleys – for removing the finished cured blocks from the autoclave.

Technical performance and characteristics:

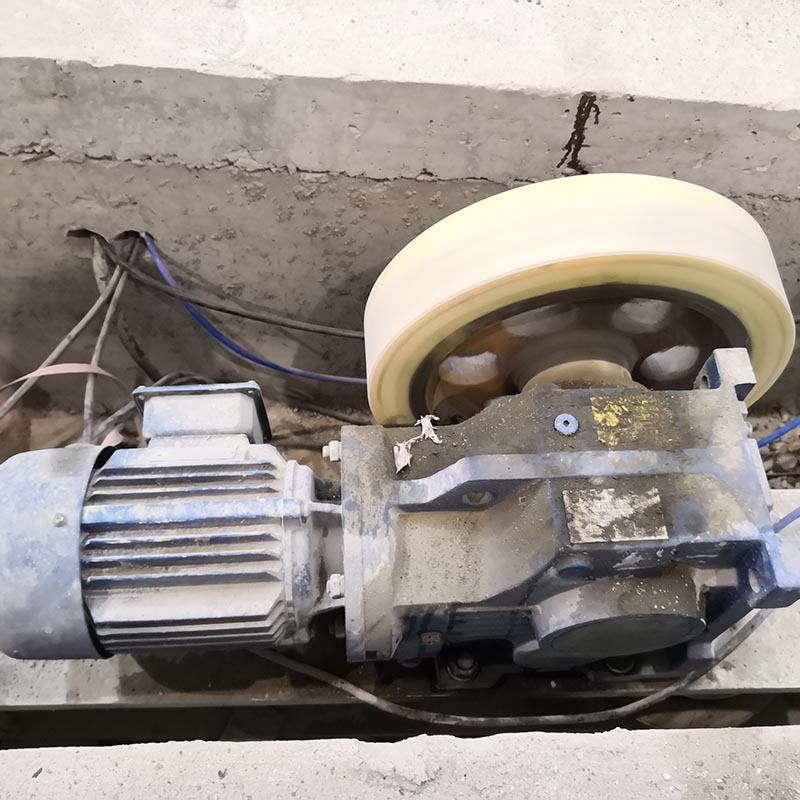

The lifting of the middle wheel of the friction wheel is controlled by the air cylinder, the rotation of the friction wheel is driven by the operation of the reducer, and the friction wheel is in contact with the friction guide rail of the mould under the action of the air cylinder and the reducer, which ensures the smooth running of the mould, and has reliable performance, compact structure, easy maintenance and so on.

Scope of supply:

Friction wheel body (including gear motor, friction wheel, cylinder, etc.), solenoid valve, triplet, and other pneumatic components.