| Device Type | Capacity | Power Consumption (kW) | Operating Pressure (Pa) | Material of Construction | Dimensions (L×W×H) | Weight (kg) | Bubble Removal Efficiency (%) | Application |

| Vacuum Bubble Remover | 20 m³/hour | 2.5 | 1000 | Stainless Steel | 1500 × 1200 × 1800 mm | 450 | 95% | Pre-Curing Process |

| Centrifugal Bubble Remover | 30 m³/hour | 3.0 | 1200 | Carbon Steel | 1800 × 1300 × 2000 mm | 520 | 90% | Slurry Preparation |

| Hydraulic Bubble Remover | 40 m³/hour | 4.0 | 1500 | Stainless Steel | 2000 × 1400 × 2200 mm | 600 | 92% | Mold Filling |

| High-Frequency Bubble Remover | 25 m³/hour | 3.5 | 1100 | Stainless Steel | 1700 × 1250 × 1900 mm | 480 | 94% | Casting Process |

| Ultrasonic Bubble Remover | 50 m³/hour | 5.0 | 1800 | Stainless Steel | 2200 × 1600 × 2300 mm | 750 | 98% | Pre-curing and Final Finishing |

Description:

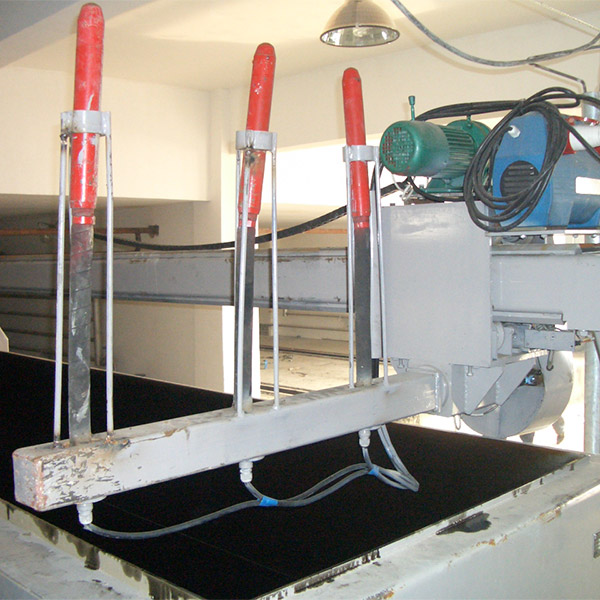

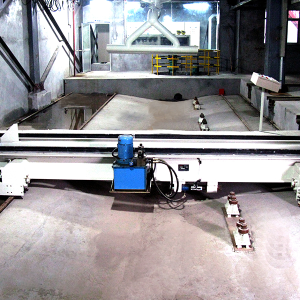

Usage: The bubble removing device mainly homogenizes the air bubbles in the slurry which has just been poured into the mold box.

Technical performance and characteristics: 16 vibrating rods lift as a whole and vibrate at the same time, which can shorten the working time

Scope of supply: Vibrating rods and brackets, hoisting drives, sheave sets, wire ropes

The Role of the Bubble Removing Device in the AAC Block Production Process:

Eliminates trapped air bubbles from the slurry mixture before it sets, ensuring uniform density and structural integrity of the aerated concrete.

- Process It Belongs To:

Casting and Pre-curing process, specifically after the slurry is poured into the mold to ensure smoothness and uniformity in the mixture. - Related Equipment Before:

Mixing Equipment – for thoroughly blending raw materials into a slurry mixture.

Pouring and Filling System – for transferring the slurry mixture into the molds. - Related Equipment After:

Pre-curing Chamber – where the mixture undergoes initial setting and curing.

Cutting Machine – utilized to cut blocks of pre-cured aerated concrete into the appropriate sizes.