The size of an aerated concrete block is one of the most important factors affecting its variety and uses. Understanding the sizes of aerated concrete blocks (from small to large) and their corresponding applications can help builders and architects make informed decisions to maximize the benefits of this innovative building material.

Introduction to AAC Blocks

AAC blocks are precast concrete products composed of quartz sand, lime, cement, water, and an aerating agent. These blocks undergo a curing process in an autoclave, where they are exposed to high temperatures and pressures. The result is a lightweight, durable building material that is widely used for walls, floors, and roofs in residential, commercial, and industrial structures.

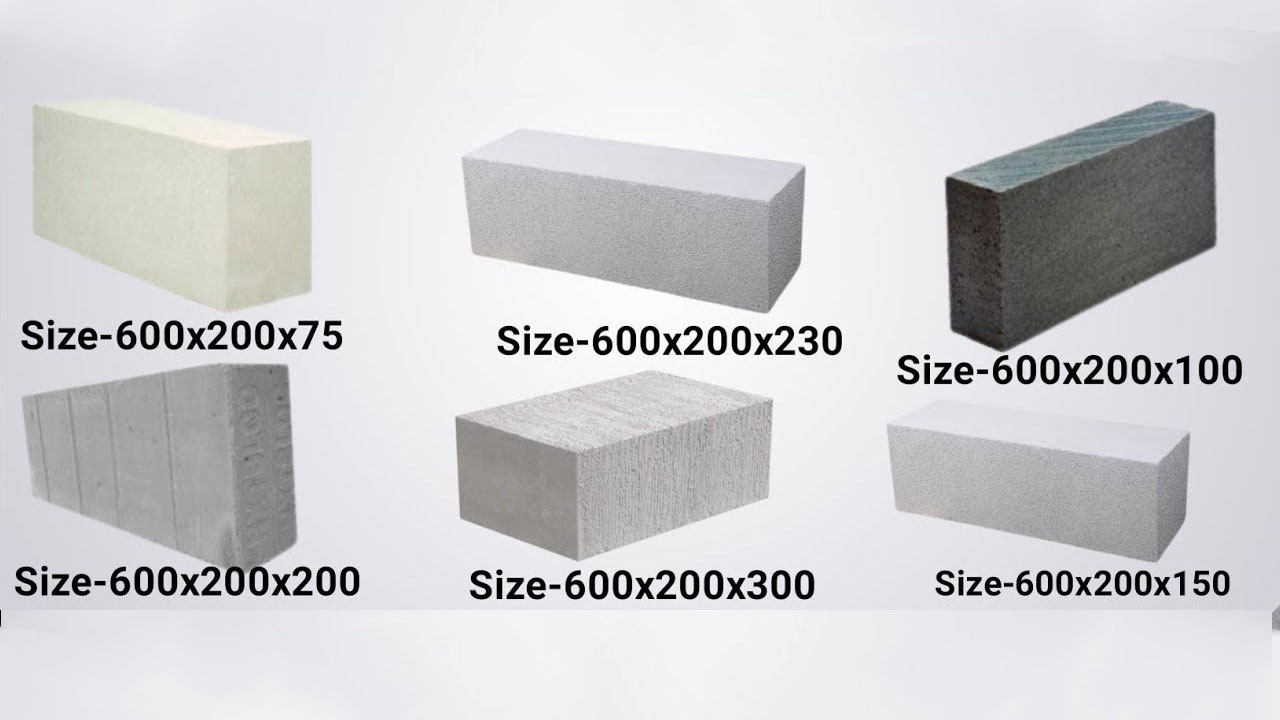

One of the key features that make AAC blocks popular is their availability in various sizes. This allows builders to select the right block dimensions for different types of construction, optimizing labor, materials, and time. Now let’s explore the three common AAC block sizes: small, medium, and large.

Importance of Choosing the Right AAC Block Size

Selecting the correct size of the AAC block is crucial for several reasons:

- Structural Integrity: The size of the block affects the strength and stability of the structure. Larger blocks provide greater surface area and load-bearing capacity, making them ideal for structural walls.

- Ease of Installation: Smaller blocks are easier to handle and install, especially in projects requiring intricate detailing or when working in confined spaces.

- Thermal Insulation: The thickness of the block determines its thermal insulation properties. Thicker blocks provide better insulation, which is essential for energy-efficient buildings.

- Cost-effectiveness: Choosing the appropriate size can save labor and material waste. Bigger blocks require less mortar and labor since they may cover a larger surface with fewer joints.

| Dimension | Mini | Medium | Large |

| Length | 400 mm to 600 mm | 600 mm | 600 mm to 625 mm |

| Weight | 200 mm to 250 mm | 200 mm to 250 mm | 200 mm to 300 mm |

| Thinckness | 75 mm to 100 mm | 150 mm to 200 mm | 250 mm to 400 mm |

| Weight | 4 to 9 kg per block | 10to 12 kg per block | 15 to 18 kg per block |

Small-Sized AAC Blocks

Small-sized AAC blocks are typically used for internal partition walls, infill construction, and smaller structures where load-bearing requirements are minimal. They are perfect for intricate construction work since they are easy to handle and allow versatility in design.

Applications

- Internal Partition Walls: Small AAC blocks are ideal for creating internal walls within buildings. They are suitable for use in offices, shops, and residences due to their excellent sound insulation.

- Non-load Bearing Walls: These blocks are used in non-load bearing applications, where the primary function of the wall is to divide space rather than support structural loads.

- Renovation and Retrofitting: Due to their lightweight and easy handling, small AAC blocks are often used in renovation projects, where they are added to existing structures without significantly increasing the overall weight of the building.

Advantages

- Lightweight: Smaller AAC bricks need less work and time to handle and transport on-site.

- Versatility: They are applicable in a broad range of settings, particularly those with limited space.

- Thermal Insulation: Although AAC blocks are smaller in size, they offer superior thermal insulation, which helps to create structures that use less energy.

Challenges

-

- Limited Load-Bearing Capacity: Small AAC blocks are not suitable for load-bearing walls, so they must be used in conjunction with other structural elements for stability.

- Installation Time: While they are easy to handle, smaller blocks may require more time to install compared to larger blocks due to the increased number of units required to cover the same area.

|

|

Medium-Sized AAC Blocks

Medium-sized AAC blocks strike a balance between small and large sizes, making them suitable for a wide range of construction projects. These blocks are often used in both load-bearing and non-load-bearing applications, providing structural stability while maintaining the benefits of AAC materials.

Applications

-

- Exterior Walls: Medium-sized AAC blocks are frequently utilized for exterior walls in both residential and commercial structures. Interiors stay cool in the summer and comfortable in the winter because of its exceptional thermal insulation.

- Load-Bearing Walls: These blocks can be used for load-bearing walls in low-rise structures, such as single-family homes and smaller commercial buildings.

- Floors and Roofs: Medium-sized blocks are also used for constructing floors and roofs, providing a solid yet lightweight alternative to traditional concrete slabs.

Advantages

-

-

- Structural Strength: Medium-sized AAC blocks offer sufficient strength for use in load-bearing walls, making them versatile for various construction needs.

- Energy Efficiency: Medium-sized AAC blocks, like other AAC blocks, offer excellent thermal insulation, which lowers the requirement for heating and cooling.

- Fire Resistance: These blocks are a safe option for both residential and commercial structures because of their strong fire resistance.

Challenges - Handling: While still lighter than traditional concrete blocks, medium-sized AAC blocks are heavier than smaller blocks and may require more effort to transport and install.

- Cost: Medium-sized AAC blocks are generally more expensive than smaller blocks due to their increased volume, but the cost is often offset by their superior performance in load-bearing applications.

Versatile

Good insulation

Easy to handle

Fire resistant

Heavier

Higher cost

More effort to install

Limited for high-rise

-

Large-Sized AAC Blocks

Large-sized AAC blocks are the preferred choice for large-scale construction projects where structural integrity and speed of installation are crucial. These blocks are typically used in high-rise buildings, industrial facilities, and other structures that require significant load-bearing capacity.

Applications

-

- Load-Bearing Walls in High-Rise Buildings: Large AAC blocks are ideal for constructing load-bearing walls in multi-story buildings. Their size and strength make them suitable for supporting heavy loads while maintaining a relatively lightweight structure.

- Industrial and Commercial Buildings: Large AAC blocks are used in industrial and commercial construction projects, where speed and efficiency are essential. Fire Resistance: These blocks are a safe option for both residential and commercial structures because to their strong fire resistance.

- Fire-Rated Walls: Due to their fire resistance, large AAC blocks are often used in fire-rated walls and partitions, particularly in industrial settings where fire safety is a top priority.

Advantages

-

- High Load-Bearing Capacity: Large-sized AAC blocks provide excellent structural support for high-rise buildings and other large-scale projects.

- Faster Construction: By using fewer blocks to cover the same area, installation time and labor expenses are decreased.

- Durability: Due to their remarkable resilience and capacity to withstand harsh weather, these blocks are ideal for industrial applications.

Challenges

-

- Handling and Transportation: Large AAC blocks are heavier and bulkier than their smaller counterparts, requiring specialized equipment for transportation and installation.

- Cost: A block’s price increases with its size. However, the cost may be justified by the reduced labor and faster construction times.

|

|

Non-standard and Customized Sizes

In addition to standard sizes, AAC blocks can also be produced in non-standard or customized dimensions to meet specific architectural or construction requirements. Customized block sizes are often requested for unique projects or where standard sizes may not be suitable.

Benefits of Custom Sizes

-

- Tailored Fit: Customized sizes can reduce the need for cutting and minimize waste.

- Faster Construction: By accelerating the building process, pre-sized blocks can save labor expenses.

- Special Applications: Custom blocks can be used in special projects such as high-rise buildings, bridges, or other structures with specific design needs.

The customization of AAC blocks adds a level of flexibility to the construction process, ensuring that the blocks fit perfectly within the design framework without compromising structural integrity.

Factors to Consider When Choosing AAC Block Size

Selecting the right AAC block size for your project involves considering several factors, including the building type, structural requirements, and environmental conditions.

Building Type

AAC block thickness varies: Residential buildings use 100–200 mm blocks, while commercial and industrial buildings need 150–300 mm blocks for load-bearing and insulation.

1. Residential Buildings:

For single-family homes or low-rise apartments, thinner blocks (100 mm to 150 mm) are typically sufficient for internal walls, while thicker blocks (150 mm to 200 mm) are used for external walls to provide adequate insulation and load-bearing capacity.

2. Commercial Buildings:

Commercial structures often require thicker AAC blocks (150 mm to 300 mm) due to higher load-bearing needs and the need for superior sound insulation between units.

3. Industrial Buildings:

In industrial settings, where larger spans and higher loads are common, AAC blocks with greater thickness (200 mm to 300 mm) are preferred for both walls and partitions.

Structural Requirements

1. Load-Bearing Capacity

For load-bearing walls, choose blocks with sufficient thickness to support the weight of the structure above. Standard sizes such as 600 mm x 200 mm x 200 mm are typically adequate for most applications.

2. Non-Load Bearing Walls

For partition walls that do not bear loads, thinner blocks (75 mm to 150 mm) can be used, which can reduce costs and installation time.

Environmental Conditions

1. Thermal Insulation:

In regions with extreme temperatures, thicker AAC blocks (200 mm to 300 mm) are ideal as they offer better thermal insulation, helping to maintain comfortable indoor temperatures and reduce energy costs.

2. Sound Insulation:

For buildings in noisy environments, such as near highways or airports, thicker blocks provide better sound insulation, creating a quieter indoor environment.

3. Fire Resistance:

AAC blocks are naturally fire-resistant, but for added protection in fire-prone areas, using blocks with greater thickness can provide additional safety.

Cost and Budget

Your budget will also play a role in determining the size of the AAC blocks you choose. While larger blocks may be more expensive initially, they can reduce overall construction costs by minimizing labor and material usage. Conversely, smaller blocks may be more cost-effective for smaller projects or when working with a limited budget.

Regional Variations in AAC Block Sizes

The sizes of AAC blocks can vary by region, based on local construction standards and practices. Let’s examine the variations in AAC block sizes seen in the Middle East, North America, and Europe.

Europe

- Standards: European standards, such as EN 771-4, dictate the dimensions of AAC blocks.\

- Common Sizes: In Europe, AAC blocks are commonly available in lengths of 600 mm, heights of 200-250 mm, and thicknesses ranging from 100 mm to 400 mm. European construction tends to emphasize precision and energy efficiency, leading to the widespread use of medium and large-sized blocks for external walls and high-rise buildings.

North America

-

- Standards: In North America, AAC blocks follow ASTM C1386 standards.

- Common Sizes: AAC blocks in North America are typically sized 24 inches (610 mm) in length, 8 inches (203 mm) in height, and thicknesses of 4-12 inches (102-305 mm). The focus is often on medium-sized blocks for residential and commercial buildings, though large blocks are also used for industrial applications.

Middle East

- Standards: The Middle East often adopts European standards, though there may be slight variations based on local regulations.

- Common Sizes: Similar to Europe, AAC blocks in the Middle East are generally available in lengths of 600 mm, heights of 200-300 mm, and thicknesses of 100-400 mm. The emphasis is on thermal insulation due to the region’s hot climate, so larger blocks are often preferred for external walls and energy-efficient buildings.

The Role of AAC Cutting Machines

Precision is key when it comes to AAC block manufacturing, and this is where AAC cutting machines come into play. These machines are designed to cut the large, pre-cured AAC blocks into precise shapes and sizes according to the project’s requirements.

How AAC Cutting Machines Work

- AAC blocks are initially produced in large “cakes” or slabs. Before the blocks are autoclaved (cured under high pressure and temperature), they are cut to the desired sizes using cutting machines.

- The cutting machine uses high-tensile wires to slice through the soft, green AAC material. This ensures that each block is accurately dimensioned, with smooth surfaces and sharp edges.

- Vertical and Horizontal Cuts: The machine performs both vertical and horizontal cuts, allowing for a variety of block sizes to be produced from a single AAC slab.

- Customization: Advanced AAC cutting machines can be programmed to cut blocks in different shapes and sizes, making it easier to produce custom blocks for specialized projects.

Types of AAC Cutting Machines

-

- Wire Cutting Machines: These are the most common types of cutting machines used in AAC manufacturing. They use multiple high-tensile wires to slice through the AAC material, producing blocks with accurate dimensions.

- Circular Cutting Machines: In some cases, circular cutting machines are used to create rounded or cylindrical shapes from AAC blocks. These machines are typically used for producing specialized AAC components like columns or arches.

- Combination Cutting Machines: Advanced models can combine different cutting techniques, allowing manufacturers to produce a variety of block sizes and shapes in a single process.

Conclusion

The versatility of AAC blocks, combined with the range of available sizes, makes them a valuable component in any construction project. By carefully considering the block size based on your specific requirements, you can achieve a balance between performance, cost, and efficiency, leading to a high-quality and sustainable building.