| Model | Load Capacity (tons) | Speed (m/min) | Rail Gauge (mm) | Power Supply | Control System | Dimensions (L x W x H) (mm) | Material of Construction | Application |

| FC-1 | 5 | 20 | 1435 | Electric (380V, 50Hz) | PLC/Remote Control | 4000 x 1500 x 1200 | Carbon Steel | Raw Material Transport, Mould Transfer |

| FC-2 | 10 | 25 | 1435 | Electric (380V, 50Hz) | PLC/Remote Control | 5000 x 2000 x 1300 | Alloy Steel | Finished Block Transfer, Mould Handling |

| FC-3 | 15 | 30 | 1435 | Electric (380V, 50Hz) | PLC/Remote Control | 5500 x 2200 x 1400 | Stainless Steel | Autoclave Loading/Unloading, Material Transport |

| FC-4 | 20 | 35 | 1435 | Electric (380V, 50Hz) | PLC/Remote Control | 6000 x 2500 x 1500 | Carbon Steel | Finished Product Transport, Mould Handling |

| FC-5 | 25 | 40 | 1435 | Electric (380V, 50Hz) | PLC/Remote Control | 6500 x 2700 x 1600 | Alloy Steel | Heavy Material Transfer, Large Batch Handling |

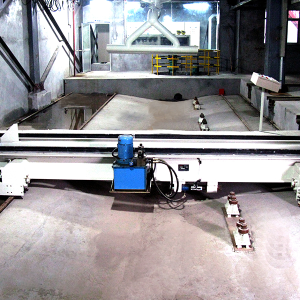

The Role of the Ferry Cart in the AAC Block Production Process:

- Role of Ferry Cart: Transports casting molds or green blocks between different processing stations, such as from the cutting station to the autoclaving area. It ensures smooth and efficient movement of materials within the production line.

- Process It Belongs To: Material Transfer and Handling process, particularly for transferring molds or blocks between cutting, curing, and autoclaving stages.

- Related Equipment Before:

Cutting Machine – for cutting the green aerated concrete blocks to the required dimensions.

Mold Removal System – for demolding the green blocks from the casting molds. - Related Equipment After:

Autoclave – used for curing green blocks under high pressure and temperature conditions.

Unloading/Stacking System – for unloading the cured blocks from the autoclave and preparing them for packaging or storage.