| Specification | Volume | Blending

Power KW) |

Blending

rotation speed (r/min) |

Homogenizing

Power (KW) |

Homogenizing

rotation speed (r/min ) |

| ASM-200 | 200 | 1.5 | 0-65 | 3 | 3000 |

| ASM-500 | 500 | 2.2 | 0-65 | 4 | 3000 |

| ASM-1000 | 1000 | 2.2-4 | 0-65 | 7.5 | 3000 |

| ASM-1500 | 1500 | 4-5.5 | 0-65 | 11 | 3000 |

| ASM-2000 | 2000 | 5.5 | 0-53 | 11 | 3000 |

| ASM-3000 | 3000 | 7.5 | 0-53 | 15 | 1500 |

| ASM-5000 | 5000 | 11 | 0-53 | 22 | 1500 |

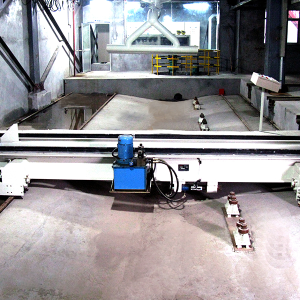

Description:

The aluminum slurry mixing machine integrates aluminum paste feeding, weighing, water addition, mixing, and aluminum liquid feeding. The unique discharging mechanism and intelligent control software effectively solve the problem of high precision requirements for aluminum powder (paste). As an independent unit in the batching system, the equipment does not affect the original operation process and can greatly reduce the floor space and on-site installation costs.

The Role of the Aluminum Slurry Mixing Machine in the AAC Block Production Process:

- Role of Aluminum Slurry Mixing Machine:

Mix aluminum powder with water to form an aluminum slurry, which is then added to the aerated concrete mix to generate gas and create a porous structure. - Process It Belongs To:

Ingredient Preparation and Gas Formation process, specifically for creating the gas-forming agent (aluminum slurry). - Related Equipment Before:

Aluminium Powder Storage and Dosing System – for storing and dosing the aluminum powder accurately before mixing.

Water Supply System – for providing the required amount of water to create the slurry. - Related Equipment After:

Main Mixer – for blending the aluminum slurry with the other raw materials (sand, cement, lime, etc.) to create the aerated concrete mixture.

Casting Molds – where the aerated concrete mix is poured, allowing the gas to form and expand, creating the final porous structure.